Background

The manufacturing quality and dynamics of modern production machines are primarily determined by the feed drive. The rack-and-pinion drives considered in this project are characterized for the use in machine tools in particular by the fact that their stiffness is independent of the range and thus long linear movements can be realized. The major issues of electromechanical drive systems which limit the achievable accuracy and dynamics are transmission errors and backlash due to manufacturing-related kinematic errors in the drive train. In terms of system theory, backlash represents a nonlinearity and thus influences the control quality of the drive system. To fulfill the requirements of modern production systems, it is necessary to compensate the backlash.

Problem statement

In rack-and-pinion drives, the backlash to be compensated occurs in the gearbox and between the rack and pinion. An effective method of minimizing backlash is to electrically preload two redundant drives. In addition to the dynamic properties of the drive train, high precision requirements are imposed. One approach to increase the accuracy of rack-and-pinion drives is the use of direct measuring systems. However, for long travel ranges these measuring systems often represent one of the central costs of the feed axis and are therefore not used. For position control, the proposed research project uses the measurement system of the drives.

Goals

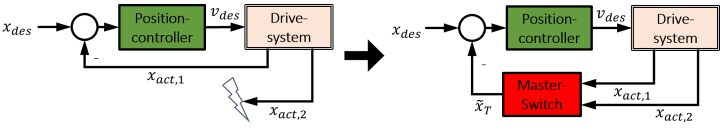

The central goal of the project is the development of a concept - called Master-Switch - which improves the precision of electrically preloaded rack-and-pinion drives with indirect position control to such an extent that they reach the precision range of directly controlled systems. In this approach, the measuring systems of both drives will be used for the first time for position control. Due to the preload, the backlash never occurs in both drives at the same time. The concept is based on the idea of compensating the backlash by switching to the encoder signal of the force-transmitting motor, thus increasing the precision. The Master-Switch will be integrated into the position control loop and extend the actual value processing without the need of additional hardware components.

Get in touch

Valentin Leipe

M.Sc.Research Assistant "Drive Systems and Motion Control"